Dambot Mini

Project Overview:

In a groundbreaking collaboration between the CHEI Lab of University of California, San Diego and the United States Army Corps of Engineers (USACE), a cutting-edge project known as DamBot Mini is set to revolutionize the world of dam inspection and maintenance. Developed as a part of a sub-task dedicated to advancing the capabilities of uncrewed ground vehicles (UGVs), the DamBot Mini project represents a significant leap forward in remote inspection technology and the creation of 3D digital twins for critical infrastructure.

Pengcheng Cao, Mechanical Engineering PhD student, and Dr. Falko Kuester, Full Professor and PI of CHEI Lab, brought forth the idea of developing a novel compact tunnel inspecting UGV in early 2023. This ambitious undertaking aims to kick off the development, integration, and field testing of the DamBot Mini, a specialized UGV designed to navigate the interior of dams and capture essential data. And later, it has been supported and sponsored by Jordan Klein and Anton Netchaev, Research Engineers at the U.S. Army Engineer Research and Development Center (ERDC). What sets DamBot Mini apart is its sophisticated sensor hardware and software stack, a fusion of cutting-edge technologies that make it a true marvel in the field of robotics and remote inspection.

A Multimodal Sensor Arsenal:

A Multimodal Sensor Arsenal:

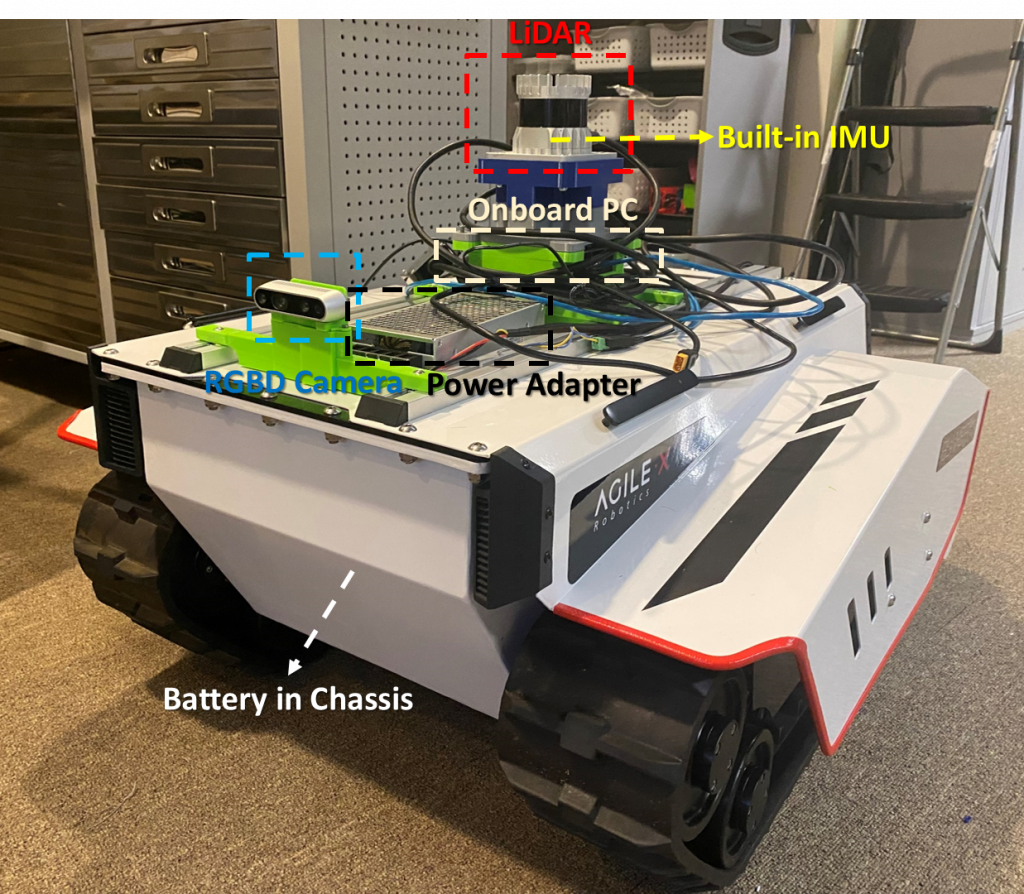

At the heart of DamBot Mini’s capabilities lies a sensor stack equipped with an impressive array of modalities. These modalities include 3D LiDAR, Intel Realsense RGBD cameras, TunnelCAM, and Looq AI sensors, all carefully chosen to serve a multitude of purposes, including path planning, real-time navigation, and the creation of 3D digital twins for remote inspections. This innovative approach allows DamBot Mini to comprehensively map the interiors of dams, enabling the acquisition of critical data for both monitoring and maintenance purposes.

Unlocking the Potential of Remote Inspection:

The DamBot Mini project is designed to address a significant challenge in dam maintenance and inspection – access to hard-to-reach or potentially hazardous areas. In many instances, the human inspection of these critical structures can be challenging, costly, or even unsafe. DamBot Mini provides a solution by offering remote inspection capabilities that can access areas that were previously off-limits to human inspectors.

Field Testing and Validation:

One of the most exciting aspects of this project is the upcoming field-testing of DamBot Mini. Scheduled for the fall of 2023, this phase will take place at the Mojave Dam or another USACE project site with prior baseline data available. This real-world testing will provide invaluable insights into the effectiveness and practicality of the technology. It marks a crucial step towards the deployment of DamBot Mini in actual dam inspection scenarios.

Aligning with the USACE Digital Twin Roadmap:

The DamBot Mini project aligns perfectly with the objectives of the USACE Digital Twin Roadmap, which aims to create digital replicas of critical infrastructure. By converging novel non-contact sensing with uncrewed inspection, this project generates actionable data and insights that contribute to the USACE’s larger vision of asset tracking and maintenance.

Vision:

Looking ahead, the goal is to transition the sensor payload developed for DamBot Mini to the USACE, where it can be integrated with the ERDC’s Argo J-8 based DamBot. This collaboration will enable the continued collection of essential data, further refining and enhancing the capabilities of these groundbreaking UGVs.

In summary, the DamBot Mini project, a collaborative effort with the US Army Corps of Engineers, signifies a significant leap forward in the realm of dam inspection and maintenance. With its state-of-the-art sensor stack and remote inspection capabilities, DamBot Mini is poised to play a vital role in ensuring the safety and integrity of critical infrastructure, pushing the boundaries of what is possible in the world of dam engineering and maintenance.